Tire design

Main “ingredients” in production of tires are: rubber, which is made from natural or synthetic rubber substances, as well as cord fabric (which can be made of metal threads), polymer and textile threads.

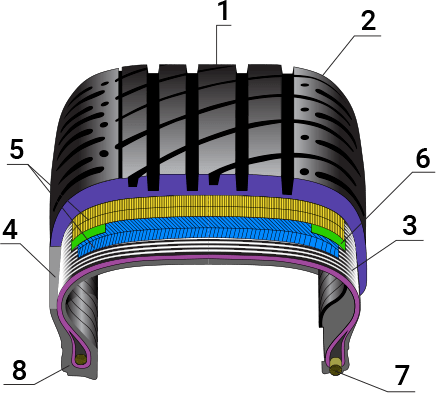

Tire structure is shown below:

Tire structure:

1 — tread;

2 — shoulder section;

3 — carcass;

4 — side part;

5 — belt and cushion ply;

6 — additional insert in shoulder section (marked green);

7 — base ring; 8 — bead section.

Tread – outer massive rubber part of tire. As a rule, it is made in the form of a pattern which ensures grip of wheel and protects ply and carcass from damage.

Shoulder section (area) – part of tire tread located between tread rib and side wall.

Tire carcass – part of tire consisting of single or several layers of rubberized cord fixed at base rings; with tire filled with gas or air, it takes up forces generated during operation of a vehicle.

Side part – side part of tire located between shoulder section and tire bead. It consists of rubber-cord layers of carcass separated by rubber layers and protected by surfacing rubber — side part.

Belt – part of tire consisting of layers of cord fabric or rubber and located between carcass and tread.

Base ring – rigid, almost inextensible part of tire consisting of one or several rings made, as a rule, of many turns of steel wire. It ensures fit and fixation of tire on wheel rim.

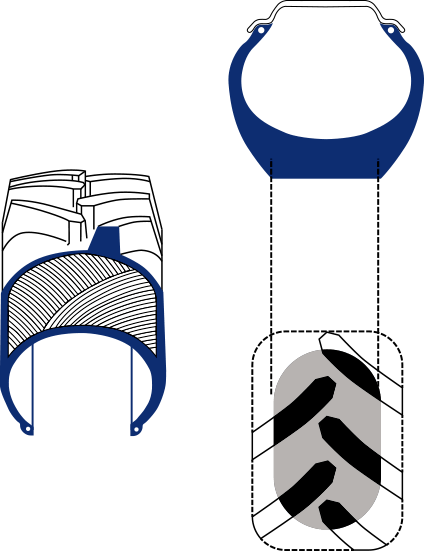

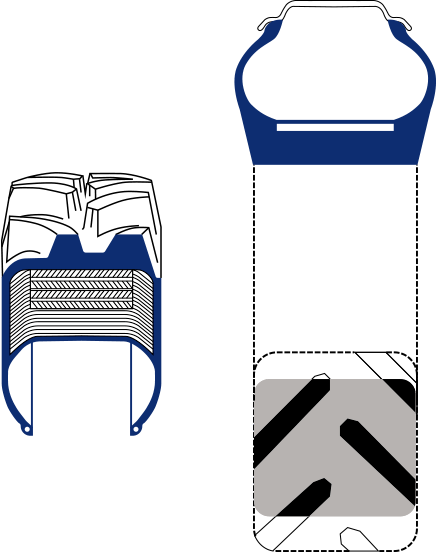

Tires are grouped by type of structure, depending on direction of cord threads in carcass:

Diagonal

Radial

Grey area: no load

Area marked by dotted line: load

| Diagonal tire | Radial tire |

| Diagonal tire has a carcass of one or more pairs of layers of cord arranged so that threads of adjacent layers intersect. In other words, tire tread, shoulder section and side part are the same layers of the carcass. Thus, all deformations of tire are easily transmitted, resulting in:

|

The effect of using radial technology in tire design is as follows: each tire part (tread, shoulder section and side part) work independently, namely, during movement, deformation is transferred to individual parts of tire without changing flat spot. The result is:

|

By method of sealing, tires are grouped in tubed and tubeless ones.

Tubed tire – is a tire in which air cavity is formed by sealing tube.

Tubeless tire — is a tire in which sealing cavity is formed by tire casing and wheel rim with the help of sealing layer of rubber with increased gas-tightness.

By configuration of cross section profile, depending on the ratio of profile height (H) to its width (B), tires are divided into full-profile tires (1) H/B> = 0.8, wide-profile (2) H/B = 0.7, low-profile and ultralow profile (3) N/B> = 0.6.

For operational purposes, tire profiles are classified as follows:

- Tire pattern — checkers or ribs separated by grooves. Tires with pattern are designed to be used mainly on roads with improved permanent surface.

- Universal pattern — checkers or ribs in the central area of tire thread and grousers along its edges. Tires with this pattern are designed to be used on roads with improved light-duty surface.

- Pattern for cross-country vehicles — high grousers separated by grooves. Tires with this pattern are designed to be used in off-road conditions and on soft soils.

- Winter pattern is a pattern where protrusions have sharp edges. Tires with this pattern are designed to be used on snowy and icy roads and can be equipped with anti-skid spikes.

- Directional pattern — asymmetrical relative to wheel radial plane.

- Pit pattern — massive protrusions of various configurations separated by grooves.

- Agricultural pattern — massive grousers in “herringbone” configuration, “hockey stick”, longitudinal

grooves.

Marking

Metric system.

Example: 800/60R32 162A8

800 – conditional profile width, mm

60 – profile height to width ratio in % (in other words, if profile width is 800 mm, profile height will make up 60% of 800 mm = 480 mm), if not specified, considered to be equal to 82.

R – radial carcass tire (if this letter is not specified, then tire is of diagonal type). “R” is often considered to be tire radius, but it’s a mistake.

32 – diameter at rim seat (corresponds to diameter of disk rim), inches

162 – load index (Max load in kg can be indicated as well) (see table)

А8 – speed index, in this case it is equal to 40 km/h.

Inch system

Example: 31х15.50-15 121B

31 – tire outer diameter, inches

15.50 – tire width, inches

15 – diameter at rim seat, the same as in metric system

121 – load index

В – speed index, in this case it is equal to 50 km/h.

Mixed system

Example: LT205/55R16 91V

- LT (optional, compulsory designation as per DOT) — tire function (P — Passenger car;

LT —Light Truck; ST — for trailers/vans/carts (Special Trailer), cannot be used for passenger

cars/pick-up trucks/trucks; T — temporary (used only for spare tires)). - 205 — profile width, mm

- 55 — profile height to width ratio, %. If not indicated, considered to be equal to 82 %.

- R — radial tire carcass (if this letter is not indicated, tire is of diagonal type). “R” is often considered

to be tire radius, but it’s a mistake. The following options are also possible: B — bias belt (belted-bias

tire. Carcass is similar to diagonal tire carcass, but there is also a belt as in radial tire), D or not

indicated — diagonal carcass type. - 16 — diameter at rim seat (corresponds to disk rim diameter), inches

- 91 — load index (in some models, Max load in kg can also be indicated)

- V — speed index (see table)

Options:

- Speed index can be put in various places of marking: 225/50SR16, 225/50SR16 89S, 225/50R16 89S

- Letter C after diameter, for example, 195/70R15C 104/102R, stands for “commercial”. This tire is designed for pick-up trucks and trucks with increased load-carrying capacity.

- After dimension, there may be letters XL, RF, SL, LL (for example, P235/75R-15 XL,

P285/35R-19 LL). They designate extra load (reinforced), standard load, light load respectively. In US P-marking, XL corresponds to maximum pressure 41 psi (280 kPa); SL and LL, 35 psi (240 kPa); in European marking, XL/RF corresponds to 42 psi (290 kPa); SL, 36 psi (250 kPa), LL is not used. This missing designation corresponds to SL option. - Letters FR (for example, 215/45 R17 87V FR) after dimension designate tire with disk rim protection. Protective plate at side part of low-profile tire protects disk and side part of tire itself from damage when passing over rough road surface at high speed.

In rare case (for example, in Michelin tires with PAX system), diameter at rim seat can be indicated in millimeters, for example, 190/65R390, such tires are called millimeter tires. If after diameter there is letter A, it means asymmetrical rim, i.e. different inner and outer diameters of rim. For example, 235/710R460A 104T — inner rim diameter is 470 mm; outer, 450 mm.

It is impossible to use millimeter tires with inch disks and vice versa, millimeter disks with inch tires.

Conversion from metric system to inch system and vice versa

| Metric system | Inch system |

| D/E-C (800/60R32) С – rim diameter D – profile width Е – profile height |

АхВ-С (31х15.50-15) А – outer diameter В – tire width С – rim diameter |

| Conversion from metric system to inch system | Conversion from inch system to metric system |

| А=С+2D*(E/100)25,4 B=D/25,4 |

D=B*25,4 E=100*(A-C)/2D/25.4 |

Load index

| LI | kg |

| 80 | 450 |

| 81 | 462 |

| 82 | 475 |

| 83 | 487 |

| 84 | 500 |

| 85 | 515 |

| 86 | 530 |

| 87 | 545 |

| 88 | 560 |

| 89 | 580 |

| 90 | 600 |

| 91 | 615 |

| 92 | 630 |

| 93 | 650 |

| 94 | 670 |

| 95 | 690 |

| 96 | 710 |

| 97 | 730 |

| 98 | 750 |

| 99 | 775 |

| 100 | 800 |

| 101 | 825 |

| LI | kg |

| 102 | 850 |

| 103 | 875 |

| 104 | 900 |

| 105 | 925 |

| 106 | 950 |

| 107 | 975 |

| 108 | 1000 |

| 109 | 1030 |

| 110 | 1060 |

| 111 | 1090 |

| 112 | 1120 |

| 113 | 1150 |

| 114 | 1180 |

| 115 | 1215 |

| 116 | 1250 |

| 117 | 1285 |

| 118 | 1320 |

| 119 | 1360 |

| 120 | 1400 |

| 121 | 1450 |

| 122 | 1500 |

| 123 | 1550 |

| LI | kg |

| 124 | 1600 |

| 125 | 1650 |

| 126 | 1700 |

| 127 | 1750 |

| 128 | 1800 |

| 129 | 1850 |

| 130 | 1900 |

| 131 | 1950 |

| 132 | 2000 |

| 133 | 2060 |

| 134 | 2120 |

| 135 | 2180 |

| 136 | 2240 |

| 137 | 2300 |

| 138 | 2360 |

| 139 | 2430 |

| 140 | 2500 |

| 141 | 2575 |

| 142 | 2650 |

| 143 | 2725 |

| 144 | 2800 |

| 145 | 2900 |

| LI | kg |

| 124 | 1600 |

| 125 | 1650 |

| 126 | 1700 |

| 127 | 1750 |

| 128 | 1800 |

| 129 | 1850 |

| 130 | 1900 |

| 131 | 1950 |

| 132 | 2000 |

| 133 | 2060 |

| 134 | 2120 |

| 135 | 2180 |

| 136 | 2240 |

| 137 | 2300 |

| 138 | 2360 |

| 139 | 2430 |

| 140 | 2500 |

| 141 | 2575 |

| 142 | 2650 |

| 143 | 2725 |

| 144 | 2800 |

| 145 | 2900 |

| LI | kg |

| 168 | 5600 |

| 169 | 5800 |

| 170 | 6000 |

| 171 | 6150 |

| 172 | 6300 |

| 173 | 6500 |

| 174 | 6700 |

| 175 | 6900 |

| 176 | 7100 |

| 177 | 7300 |

| 178 | 7500 |

| 179 | 7750 |

| 180 | 8000 |

| 181 | 8250 |

| 182 | 8500 |

| 183 | 8750 |

| 184 | 9000 |

| 185 | 9250 |

| 186 | 9500 |

| 187 | 9750 |

| 188 | 10000 |

| 189 | 10300 |

| LI | kg |

| 190 | 10600 |

| 191 | 10900 |

| 192 | 11200 |

| 193 | 11500 |

| 194 | 11800 |

| 195 | 12150 |

| 196 | 12500 |

| 197 | 12850 |

| 198 | 13200 |

| 199 | 13600 |

| 200 | 14000 |

| 201 | 14500 |

| 202 | 15000 |

| 203 | 15500 |

| 204 | 16000 |

| 205 | 16500 |

| 206 | 17000 |

| 207 | 17500 |

| 208 | 18000 |

| 209 | 18500 |

| 210 | 19000 |

| 211 | 19500 |

Speed index

| Speed index | Speed limit, km/h | Speed index | Speed limit, km/h |

| A1 | 5 | K | 110 |

| A2 | 10 | L | 120 |

| A3 | 15 | M | 130 |

| A4 | 20 | N | 140 |

| A5 | 25 | P | 150 |

| A6 | 30 | Q | 160 |

| A7 | 35 | R | 170 |

| A8 | 40 | S | 180 |

| B | 50 | T | 190 |

| C | 60 | U | 200 |

| D | 65 | H | 210 |

| E | 70 | V | 240 |

| F | 80 | W | 270 |

| G | 90 | Y | 300 |

| J | 100 | ZR | over 240 |