Twin wheels

Recently, farmers have been paying more and more attention to the issue of soil compaction as one of the most powerful factors of its degradation. Soil compaction is caused by pressure of wheeled and caterpillar vehicles on soil. For normal development of a plant, there should be a balance of solid soil particles, water and air in the ratio of 50:30:20. If this proportion is violated, yield is significantly reduced, as evidenced by repeated studies conducted by American agricultural experts: grain yield decreased by 8%-13%.

Over the years, compaction may increase. As a result of pressure on soil caused by tractors and working equipment, so-called “plow sole” is formed at a certain depth, which complicates penetration of roots into soil depth and access of necessary moisture and nutrients. To eliminate this compaction it is necessary to carry out cultivation works which entail considerable investment of funds, fuel and time consumption.

Figure below shows the cut of upper layers of un-compacted and over-compacted soil. It clearly demonstrates how much the space for air and water is reduced due to influence of wheels and

caterpillars of agricultural machinery.

To preserve and restore soil fertility, it is necessary to grow crops without destroying and compacting soil.

The question that has to be answered is how to till soil without compacting it?

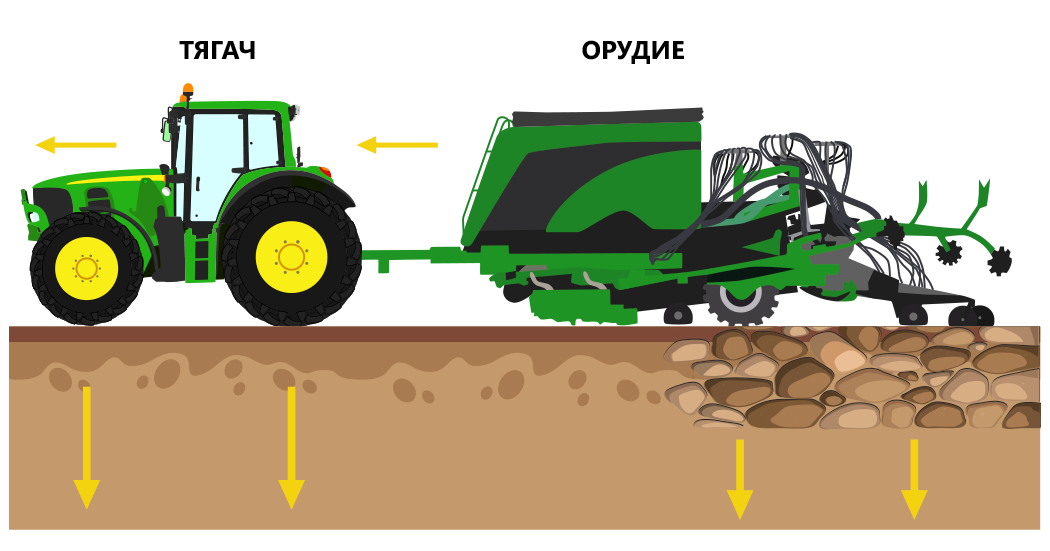

In this article we will talk about the most effective way to solve this problem. All machinery can be represented as a system for tillage and treatment of plants, consisting of two parts: a tilling machine and a tractor, which hauls this machine.

Tractive power is a key indicator that determines ability of machine to pull tilling machines.

Drawbar power is an indicator of tractor performance, and depends on drawbar pulling force at operating speed.

Towing performance of a wheeled tractor depends on its weight, flat spot of tires and pressure it exerts on the ground. It has been proven that larger flat spot causes greater drawbar pull. You can achieve the desired results by doubling and tripling front and rear wheels of machines having set lower tire pressure.

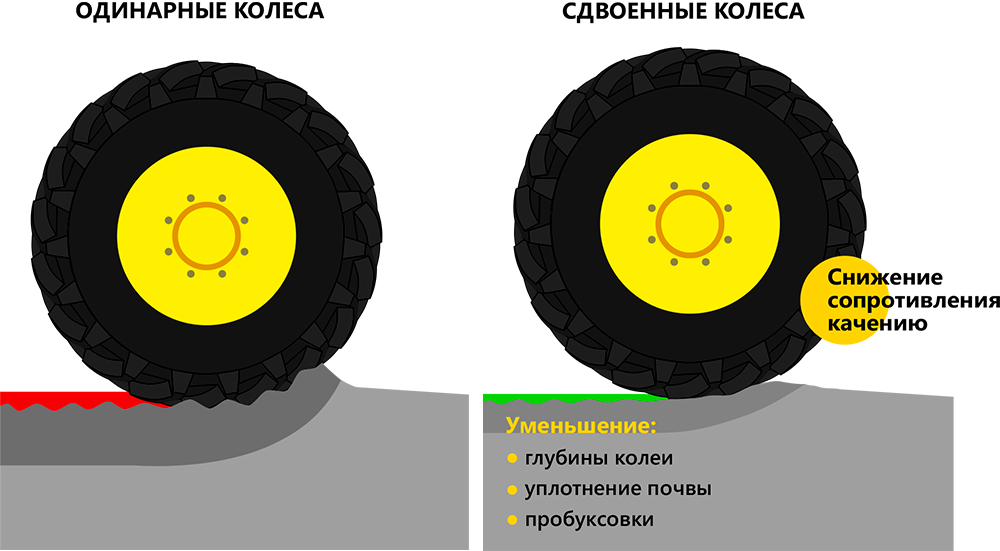

Twin wheels reduce specific pressure on soil, decrease compaction following tractor tracks by 1.5–2 times and increase off-road capability of machines on wet soils (especially during spring field work). They increase drawbar pull and significantly reduce fuel consumption (by 15%-25%). Twin wheels transfer power to soil more efficiently than single wheels (assuming equal efficiency of power transmission of machines), and therefore it is possible to increase tilled area by 10%, thus saving time and fuel.

Another important indicator is skidding rate. Tire pressure on bearing surface leads to a slight displacement of a part of soil; as a result, skidding occurs and forward speed is decreased. Typically all-wheel drive tractors are characterized by 15% skidding, that is, every eighth wheel spin does not contribute to advancement, but it still consumes fuel. Usually, twin wheels system allows to get maximum tractive power, approximately at 3-5% skidding. As compared to single wheels, power is increased by 10-15%, and useful work is not performed only at every 25th wheel spin.

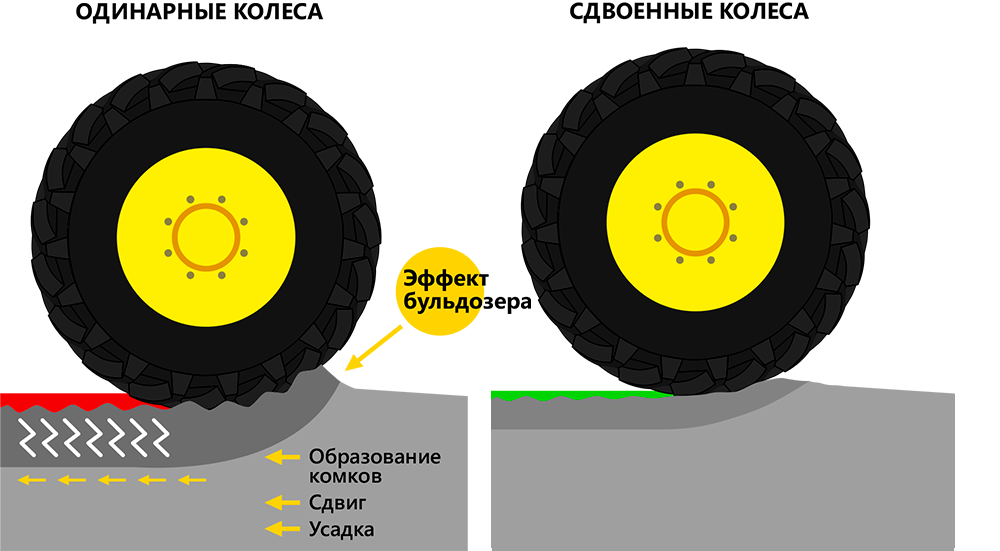

According to independent studies, every centimeter of tire sinking into soil leads to 10% increase in fuel consumption. This is due to the “bulldozer effect” caused by high rolling resistance of tires, which, with high air pressure, cut into soil. When tires sink by 2 cm, fuel consumption increases by 20%, with 10 cm sinking consumption increases by more than 50%. The only solution to deep track problem is to reduce air pressure in tires. In this case, we need to reduce load on the tires as well, which reduces performance of machinery. The best way-out is to install twin wheels and to decrease pressure in tires. Combination of these methods ensures best results.

Particular attention should be paid to inter-row tillage, it should be carried out in a timely manner within a short time. Such works include: destruction of soil crust; loosening of soil; weed control; thinning or bunching of plants in rows; hilling; fertilization during the period of growth or dressing of plants; irrigation; pest and diseases control of cultivated crops. Tillage depth is set according to its purpose, state of plants and weather conditions. In dry conditions, tillage is carried out without pulling out lowerwet layers of soil, and under conditions of excessive moisture, on the contrary, deeper loosening is used to facilitate access of air to plants roots.

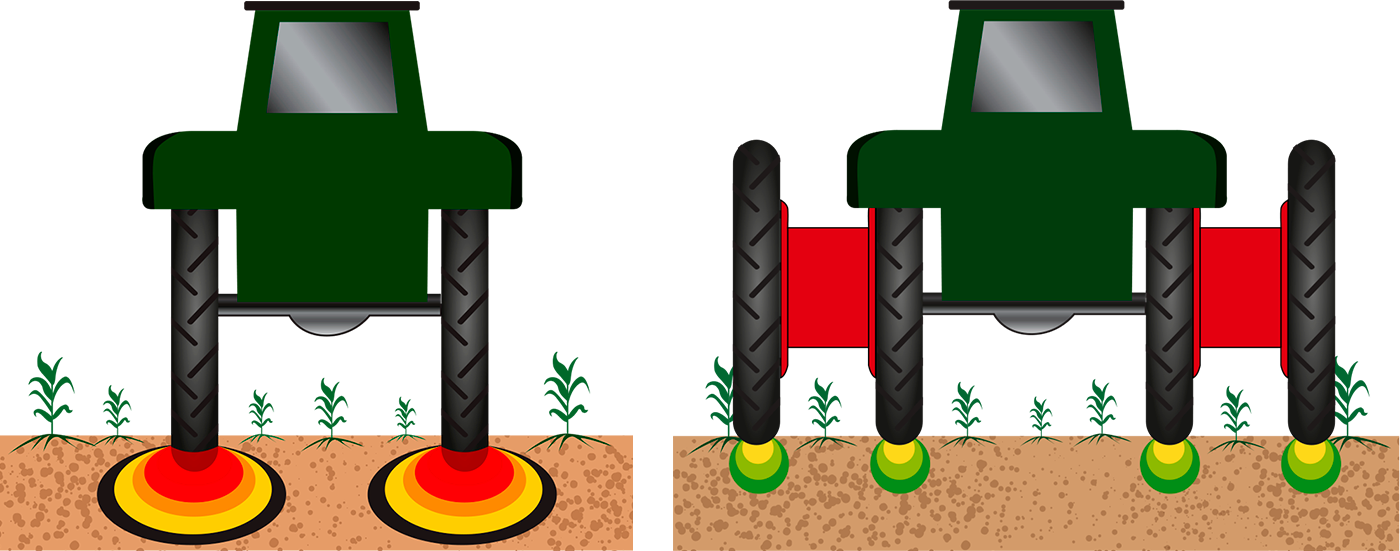

A protective area is kept between plants in rows and tilled part between rows, so that cultivated plants are not damaged and are not covered with soil during tillage.

Such tillage is carried out with tractors which are equipped with narrow single wheels. However, their pressure on soil is very high, which causes excessive soil compaction, formation of lumps, rut, prevents moisture from penetrating plant root system, and flat spot (adhesion) is limited, therefore, traction and tillage speed are limited. On loose soil, such tractors slip. To eliminate this drawback, all-wheel-drive tractors were created; however, such machines are notable for their heavy weight. Thus, the issue of skidding was resolved, but the issue of compaction of soil was not. To date, the ONLY way out of this situation is to install twin narrow wheels on a tractor for the required track and spacing.

Our company specializes in integrated wheel solutions. Production capabilities allow us to solve wheel problems of any complexity and for any machinery. Twin wheels can be used to equip machines produced by any manufacturer, ranging from domestic (MTZ, HTZ, YuMZ) to imported (John Deere, Case, Massey Ferguson, NewHolland, Deutz Fahr, Fandt, Claas, and many others).